RodaFIT®, a special production process, which allows Rodacciai to supply products, which satisfy the request of the market to have zero defects. A better quality that Rodacciai can obtain and certify, not only thanks to 40 years experience, but also thanks to experience in current induced controls, but also and especially thanks to a particular technical production device in each phase of the production process. This foresees the start from the billets, the consequent rolling, eventual thermal treatment and cold finishing.

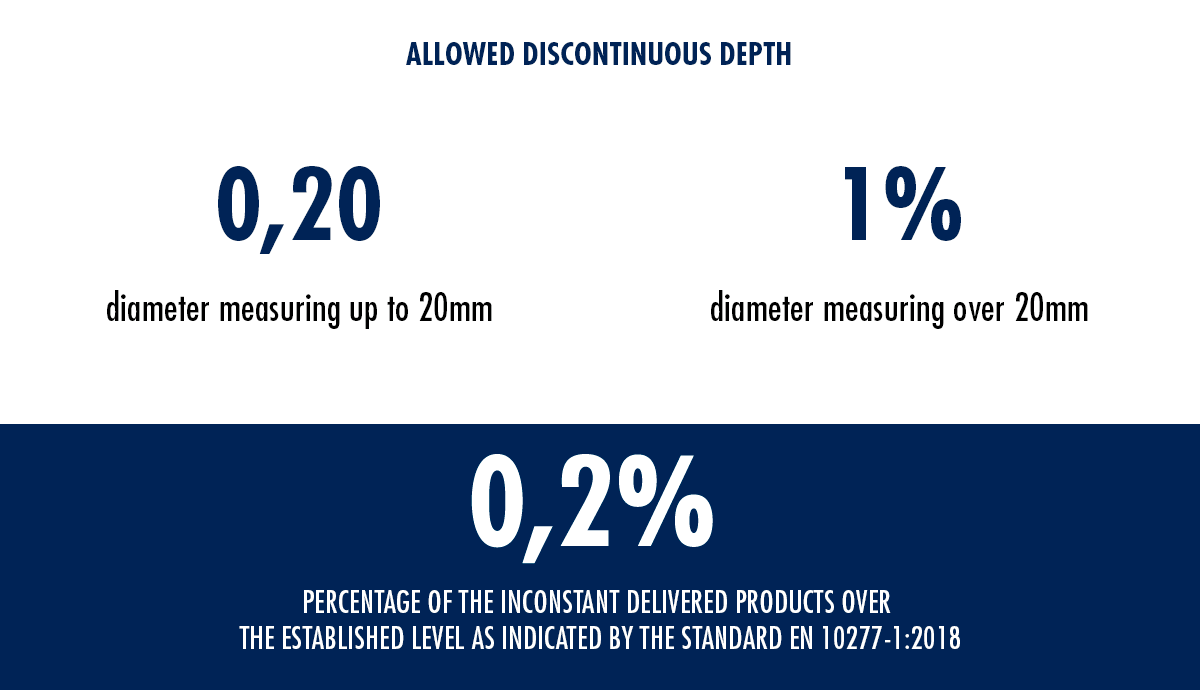

RodaFIT® PROCESS ALLOWS TO OBTAIN A QUALITY OF THE SURFACE, WHICH WE CAN GUARANTEE AND CERTIFY ON THE DRAWN ROUND:

PROCESS

All the production phases, also the rolling and the consequent cold finishing, are made at Rodacciai warehouses.

- Selection of best suppliers of billets

- Proprietary lamination process

- Deep know-how of cold-drawing techniques

WHAT RODAFIT® PROCESS

IS USED FOR?

- When even a few faulty pieces are not allowed

- Turned parts (bushes for example) are grasped on rubber hoses

- When there are security parts where internal integrity is not fundamental

- Where high quality is required for drawn bars